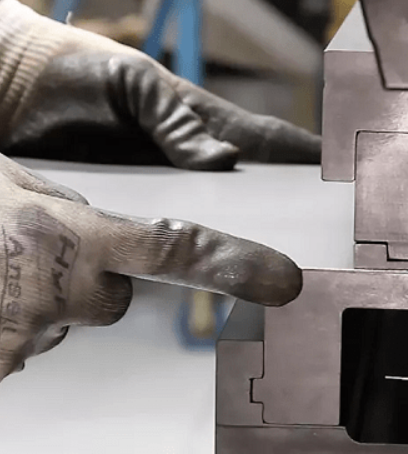

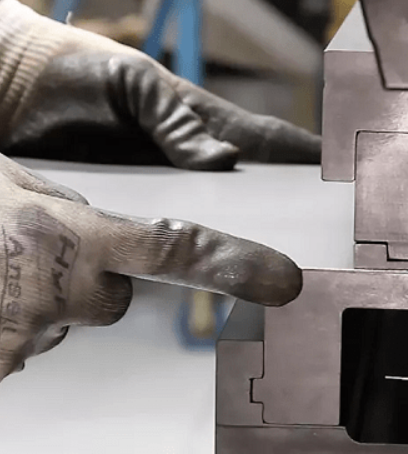

Sheet metal fabrication is not merely a manufacturing process; it is a meticulous art form that marries scientific precision with artisanal craftsmanship. At its core, this intricate process involves the transformation of flat metal sheets into complex and functional components. The journey begins with the initial precision cutting of metal sheets, a crucial step that sets the foundation for the entire fabrication process. As the sheets undergo meticulous bending and assembling techniques, a masterpiece of accuracy takes shape. Advanced technologies, including CNC machining and laser cutting, synergize with skilled craftsmanship, ensuring that every component produced adheres to the most stringent design specifications with unparalleled precision. The art of sheet metal fabrication is a testament to the relentless pursuit of perfection in engineering.

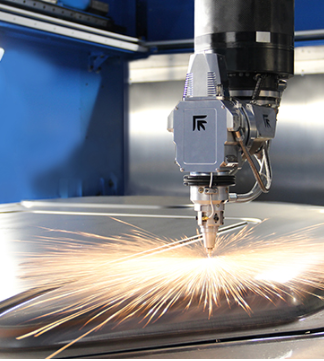

Embracing a revolution in efficiency, our sheet metal fabrication integrates advanced automation at every stage. Computer numerical control (CNC) machining takes center stage, accelerating production timelines while enhancing precision, consistency, and repeatability. Laser cutting machines, guided by intricate digital designs, swiftly and accurately shape metal sheets, showcasing our commitment to efficiency through automation. The marriage of skilled craftsmanship with cutting-edge automation defines our sheet metal fabrication process, setting new benchmarks for efficiency in modern manufacturing. The result is a seamless fusion of human expertise and technological prowess, redefining the landscape of sheet metal fabrication.

In an era where sustainability is imperative, our sheet metal fabrication takes center stage in fostering eco-friendly practices. We actively minimize material wastage through optimized cutting and nesting techniques, aligning our practices with environmentally conscious manufacturing. The longevity of our sheet metal components inherently contributes to sustainable practices by reducing the need for frequent replacements. Our sheet metal fabrication stands as a responsible choice, aligning seamlessly with the global commitment to sustainable manufacturing. In this convergence of efficiency, precision, and sustainability, sheet metal fabrication paves the way for a future where manufacturing practices prioritize environmental stewardship without compromising on quality or innovation.

Our sheet metal fabrication expertise transcends conventional boundaries, finding applications across diverse industries. Automotive, aerospace, electronics, and construction sectors all benefit from the versatility of our sheet metal fabrication capabilities. Crafting robust chassis components for automobiles, intricate aircraft parts, precision enclosures for electronics, and structural components for construction projects – our sheet metal fabrication is the cornerstone that supports innovation and reliability across a spectrum of industries. Our commitment to versatility positions us as a trusted partner for projects of varied complexities.

Our sheet metal fabrication is not merely a service; it's a collaborative partnership. We embrace a client-centric approach, prioritizing effective communication, transparency, and understanding of our clients' unique needs. Our collaborative process involves close consultation, where client inputs shape the direction of the sheet metal fabrication project. Whether it's a prototype or a large-scale production run, our client-centric approach ensures that the final outcome aligns seamlessly with the client's vision. It establishes us as a trusted partner in sheet metal fabrication, where the client's satisfaction is at the forefront of every decision and action.

Welcome to Lvda Metal, a distinguished metal manufacturing company equipped with cutting-edge production facilities and a dedicated team of professionals ensuring superior quality.

Our comprehensive services encompass a one-stop solution for die-casting molds, injection molds, CNC machining, sheet metal processing, surface treatment, and packaging. With advanced technology and a commitment to excellence, we deliver precision-engineered products tailored to your specifications.

At Lvda Metal, our mission is to enhance the quality while minimizing costs for our customers. We have cultivated long-term partnerships with renowned companies, earning widespread acclaim for our commitment to excellence. As we continue to grow, we eagerly anticipate forging new collaborations, extending our expertise, and achieving mutual success with more valued customers.

With fourteen years of experience in manufacturing metal products, LVDA boasts advanced equipment and a professional technical team. The company has emerged as a leading manufacturer and solution provider in the industry, ensuring top-notch quality and service.

LVDA leverages its expansive production scale to drive down costs while continually innovating to enhance production efficiency. By embracing technological advancements, we optimize processes to deliver competitive pricing without compromising on quality.

Beyond mere production, LVDA offers invaluable engineering expertise throughout the manufacturing journey. From material selection and custom prototyping advice to cost-saving insights, our dedicated team provides expert guidance, ensuring optimal outcomes for every project.

As an ISO9001/IATF16949 certified factory, LVDA upholds the highest standards of quality assurance. We furnish comprehensive testing equipment and material certification reports, alongside tailored first sample inspection plans, guaranteeing the integrity of every component.

Sheet metal fabrication employs a variety of materials, including steel, aluminum, and stainless steel, chosen based on specific project requirements for strength, durability, and corrosion resistance.

Precision in sheet metal fabrication is achieved through advanced techniques like CNC machining, laser cutting, and press braking, ensuring accurate dimensions and tight tolerances in the final products.

Sheet metal fabrication caters to diverse industries, including automotive, aerospace, electronics, and construction, showcasing its versatility in producing components for a wide array of applications.

Absolutely. Sheet metal fabrication is highly customizable, allowing for the realization of unique designs and specific client requirements, ensuring tailored solutions for various projects.

Copyright © 2024 by Dongguan Lvda Metal Products Co., Ltd. - Privacy policy