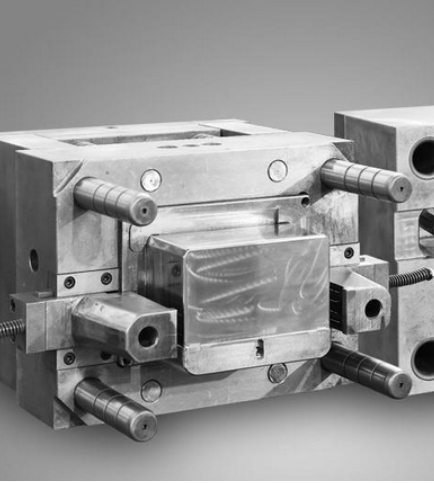

The resilience of die casting molds under extreme conditions is a testament to their thermodynamic prowess. Subjected to high temperatures and pressures during the casting process, these molds undergo meticulous heat treatment processes and feature robust constructions. The integration of advanced cooling channels ensures efficient temperature control, preventing thermal stresses and enhancing the mold's ability to endure challenging manufacturing environments. This thermodynamic resilience not only extends the lifespan of the die casting mold but also contributes to the production of defect-free, high-quality metal components.

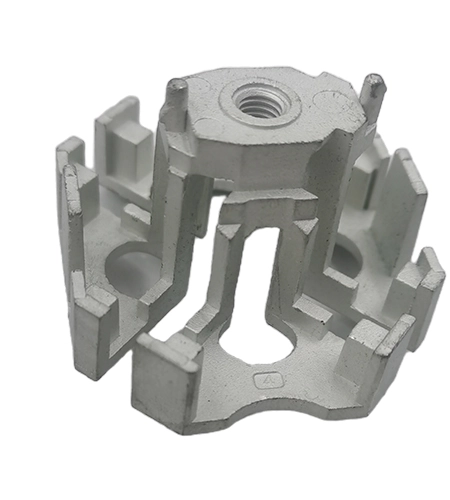

The art of die casting mold creation involves a discerning eye for material selection, a critical factor influencing both durability and performance. At our manufacturing facility, we emphasize material mastery, choosing robust tool steel and resilient aluminum alloys. This careful selection ensures not only the longevity of our die casting molds but also their ability to withstand the rigors of high temperatures and pressures during the casting process. The mastery of materials becomes a cornerstone, empowering our die casting molds to be reliable workhorses, consistently delivering high-quality and precision-engineered metal components.

In our commitment to responsible manufacturing, sustainability is not just a consideration; it is a guiding principle embedded in the design and production of our die casting molds. From the utilization of energy-efficient processes to the selection of eco-friendly materials, our die casting molds exemplify environmentally conscious practices. This dedication to sustainability extends beyond compliance; it positions our die casting molds as symbols of responsible and forward-thinking production in the realm of precision metal manufacturing. As advocates for sustainable practices, our die casting molds become catalysts for positive change, reflecting our commitment to creating a greener and more environmentally friendly future.

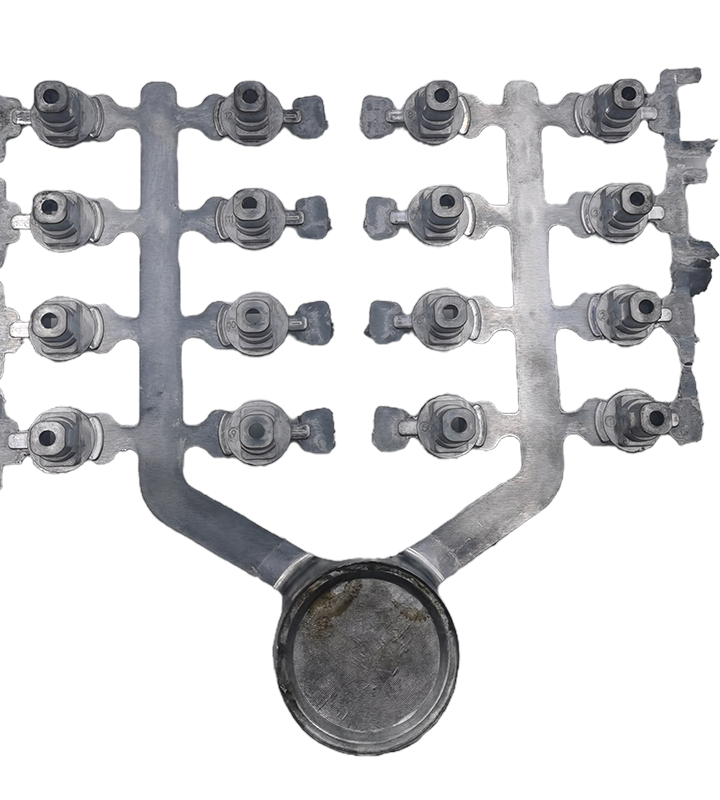

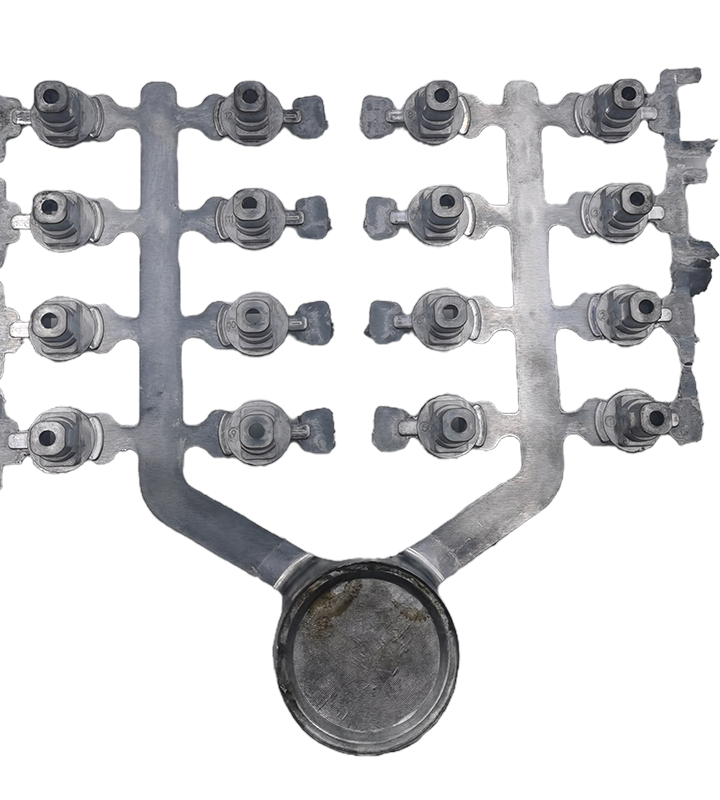

Strategic design in die casting molds extends beyond intricate shapes; it encompasses the precise management of the cooling process. Our innovative engineering solutions incorporate strategically designed cooling channels within the mold structure. This meticulous approach optimizes temperature control, preventing defects such as porosity and warping in the final cast components. Our die casting molds are engineered to facilitate uniform solidification, ensuring that the cooling process is a precise and integral element in the production of flawless metal components. The commitment to cooling precision becomes a testament to our unwavering pursuit of perfection in die casting mold design.

Quality control is ingrained in the very fabric of our die casting molds, ensuring a level of consistency and repeatability that sets the industry standard. Rigorous inspections, dimensional checks, and performance evaluations are conducted at each stage of the die casting mold lifecycle. This commitment to quality control establishes our die casting molds as reliable instruments, capable of delivering consistent and repeatable results. Our dedication to maintaining the highest industry standards guarantees that each mold contributes to the production of components of uncompromising quality. The assurance of quality control becomes a cornerstone, defining our die casting molds as symbols of precision, reliability, and excellence in the manufacturing landscape.

Welcome to Lvda Metal, a distinguished metal manufacturing company equipped with cutting-edge production facilities and a dedicated team of professionals ensuring superior quality.

Our comprehensive services encompass a one-stop solution for die-casting molds, injection molds, CNC machining, sheet metal processing, surface treatment, and packaging. With advanced technology and a commitment to excellence, we deliver precision-engineered products tailored to your specifications.

At Lvda Metal, our mission is to enhance the quality while minimizing costs for our customers. We have cultivated long-term partnerships with renowned companies, earning widespread acclaim for our commitment to excellence. As we continue to grow, we eagerly anticipate forging new collaborations, extending our expertise, and achieving mutual success with more valued customers.

With fourteen years of experience in manufacturing metal products, LVDA boasts advanced equipment and a professional technical team. The company has emerged as a leading manufacturer and solution provider in the industry, ensuring top-notch quality and service.

LVDA leverages its expansive production scale to drive down costs while continually innovating to enhance production efficiency. By embracing technological advancements, we optimize processes to deliver competitive pricing without compromising on quality.

Beyond mere production, LVDA offers invaluable engineering expertise throughout the manufacturing journey. From material selection and custom prototyping advice to cost-saving insights, our dedicated team provides expert guidance, ensuring optimal outcomes for every project.

As an ISO9001/IATF16949 certified factory, LVDA upholds the highest standards of quality assurance. We furnish comprehensive testing equipment and material certification reports, alongside tailored first sample inspection plans, guaranteeing the integrity of every component.

Die casting molds are often crafted from durable materials like tool steel or aluminum alloys. Material choice significantly influences mold lifespan, thermal conductivity, and resistance to wear, ensuring optimal performance and longevity.

Our die casting mold design incorporates advanced CAD/CAM technologies and meticulous engineering expertise. Rigorous testing and validation processes guarantee the mold's ability to achieve and maintain tight tolerances for intricate parts.

Our quality control includes thorough inspections, dimensional checks, and performance evaluations at every stage of the die casting mold lifecycle. This commitment to precision guarantees consistent and repeatable results, meeting the highest industry standards.

Our die casting molds incorporate strategically designed cooling channels, optimizing temperature control. This meticulous approach minimizes thermal stresses, prevents defects, and enhances the overall quality of the final cast components.

Copyright © 2024 by Dongguan Lvda Metal Products Co., Ltd. - Privacy policy