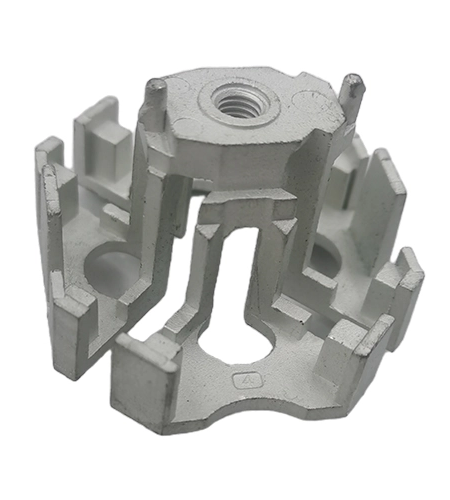

At the very heart of our aluminum die casting service lies a remarkable strength-to-weight ratio that sets it apart in the manufacturing realm. We capitalize on the inherent lightweight properties of aluminum and go a step further by enhancing these attributes during the casting process. The end result is components that not only exhibit exceptional strength but also maintain an optimal balance of weight. This unique combination positions our aluminum die casting service as the preferred choice for applications that demand structural integrity without compromise on overall weight considerations. Industries ranging from automotive to consumer electronics benefit from this unique blend, providing solutions where robustness meets efficiency.

As sustainability gains prominence, our aluminum die casting service emerges as an environmentally friendly manufacturing option. Aluminum's complete recyclability without compromising its mechanical properties aligns seamlessly with our commitment to eco-friendly practices. Choosing our service means actively participating in resource conservation and reducing environmental impact. Beyond precision and efficiency, our aluminum die casting service champions sustainability, meeting the growing demand for environmentally responsible manufacturing processes across industries. It's not just about producing components; it's about doing so in a manner that aligns with the principles of environmental stewardship.

As technology advances, our aluminum die casting service remains at the forefront, actively shaping the future of manufacturing. The amalgamation of precision, strength, efficient heat dissipation, cost-effectiveness, versatility, sustainability, and quality assurance positions our service as a key player in the ongoing evolution of manufacturing processes. Its adaptability to diverse industry needs and its substantial contribution to the production of complex, reliable, and precisely engineered components underscore its significance in driving innovation and progress. Our aluminum die casting service isn't just a method; it's a transformative force shaping the landscape of future industrial practices. It's about more than manufacturing; it's about leading the way into a future where ingenuity and excellence converge.

Beyond precision and mechanical properties, our aluminum die casting service embodies cost-effective manufacturing. The process not only yields components with exceptional mechanical properties but also delivers an excellent surface finish. This often eliminates the need for additional finishing processes, saving both time and costs. The smooth and aesthetically pleasing surfaces of die-cast components not only meet but exceed industry standards. Our aluminum die casting service proves that cost-effectiveness and superior surface finishes can coexist, making it the preferred choice for manufacturing intricate parts across diverse industries. It's about more than efficiency; it's about delivering excellence without compromise.

Our aluminum die casting service goes beyond precision and strength; it becomes a gateway to versatile design possibilities. Engineers and designers benefit from the flexibility our service offers, allowing the creation of components with complex geometries, thin walls, and intricate details. The moldability of aluminum during the die casting process empowers the production of shapes and designs that might be challenging with other manufacturing methods. This versatility makes our aluminum die casting service a catalyst for innovation, providing a canvas for creative design solutions across a myriad of industries. It's not just about manufacturing; it's about unleashing creativity and pushing the boundaries of what's possible.

Welcome to Lvda Metal, a distinguished metal manufacturing company equipped with cutting-edge production facilities and a dedicated team of professionals ensuring superior quality.

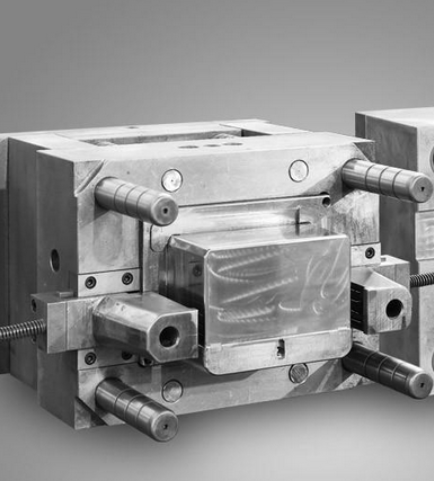

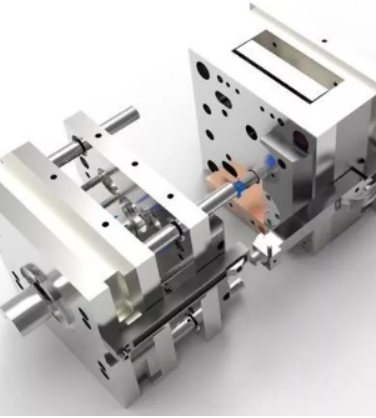

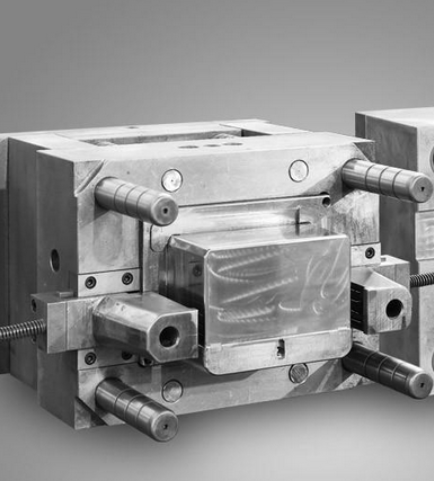

Our comprehensive services encompass a one-stop solution for die-casting molds, injection molds, CNC machining, sheet metal processing, surface treatment, and packaging. With advanced technology and a commitment to excellence, we deliver precision-engineered products tailored to your specifications.

At Lvda Metal, our mission is to enhance the quality while minimizing costs for our customers. We have cultivated long-term partnerships with renowned companies, earning widespread acclaim for our commitment to excellence. As we continue to grow, we eagerly anticipate forging new collaborations, extending our expertise, and achieving mutual success with more valued customers.

With fourteen years of experience in manufacturing metal products, LVDA boasts advanced equipment and a professional technical team. The company has emerged as a leading manufacturer and solution provider in the industry, ensuring top-notch quality and service.

LVDA leverages its expansive production scale to drive down costs while continually innovating to enhance production efficiency. By embracing technological advancements, we optimize processes to deliver competitive pricing without compromising on quality.

Beyond mere production, LVDA offers invaluable engineering expertise throughout the manufacturing journey. From material selection and custom prototyping advice to cost-saving insights, our dedicated team provides expert guidance, ensuring optimal outcomes for every project.

As an ISO9001/IATF16949 certified factory, LVDA upholds the highest standards of quality assurance. We furnish comprehensive testing equipment and material certification reports, alongside tailored first sample inspection plans, guaranteeing the integrity of every component.

Aluminum die casting service enhances component strength, providing a remarkable strength-to-weight ratio crucial for demanding applications.

Aluminum die casting service reduces costs by delivering components with excellent surface finishes, often eliminating the need for additional finishing processes.

Absolutely, aluminum die casting excels in versatility, allowing for the production of intricate shapes and designs with precision and ease.

Industries such as electronics and automotive leverage the efficient heat dissipation of aluminum die casting for enhanced thermal performance.

Copyright © 2024 by Dongguan Lvda Metal Products Co., Ltd. - Privacy policy