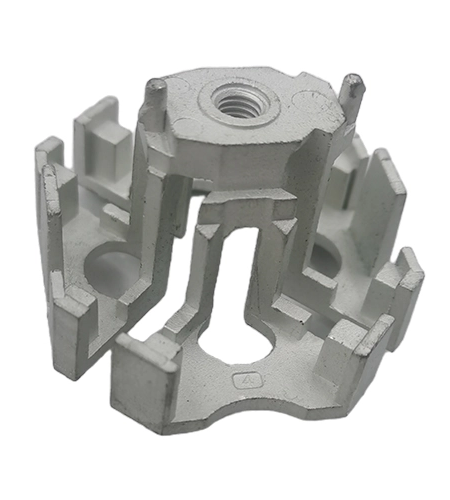

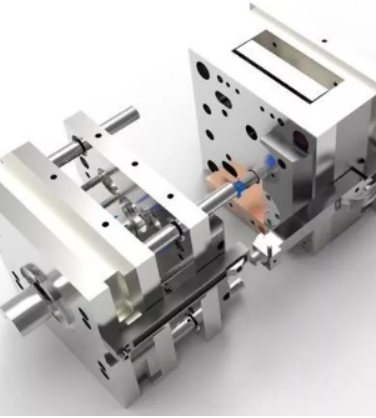

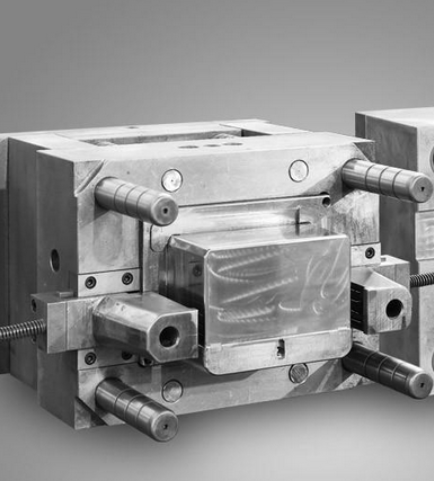

Our aluminum die casting service stands as a pinnacle of precision in the manufacturing landscape. Leveraging cutting-edge technology, we meticulously execute the process by injecting molten aluminum into intricately designed molds under high pressure. This meticulous approach ensures the creation of components with unparalleled dimensional accuracy. The precision embedded in our aluminum die casting service is a testament to our unwavering commitment to delivering products that not only meet but often surpass the stringent demands of various industries. From aerospace to automotive, our precision-crafted components find applications in sectors where accuracy is non-negotiable.

The essence of our aluminum die casting service lies in the remarkable strength-to-weight ratio it imparts to components. By harnessing the intrinsic lightweight properties of aluminum and further enhancing them through the die casting process, we create components that exhibit exceptional strength without compromising overall weight. This distinctive advantage positions our service as the preferred choice for industries where both structural robustness and operational efficiency are paramount. From heavy-duty industrial components to intricate electronic parts, our aluminum die casting service unlocks the perfect balance of strength and efficiency, providing a competitive edge to our clients.

Efficient heat dissipation stands as a defining feature of our aluminum die casting service, redefining thermal performance across various applications. Particularly crucial in industries where temperature management is critical, our components boast superior thermal conductivity. This attribute ensures that heat is effectively transferred, contributing significantly to enhanced overall performance and prolonged product lifespan. Whether in electronic devices or automotive systems, our aluminum die casting service sets a new standard for efficient heat dissipation, ensuring optimal functionality even in the most demanding environments. It's not just about creating components; it's about enhancing performance and reliability through innovative solutions.

Beyond precision and mechanical properties, our aluminum die casting service embodies cost-effective manufacturing. The process not only yields components with exceptional mechanical properties but also delivers an excellent surface finish. This often eliminates the need for additional finishing processes, saving both time and costs. The smooth and aesthetically pleasing surfaces of die-cast components not only meet but exceed industry standards. Our aluminum die casting service proves that cost-effectiveness and superior surface finishes can coexist, making it the preferred choice for manufacturing intricate parts across diverse industries. It's about more than efficiency; it's about delivering excellence without compromise.

In the competitive landscape of manufacturing, our aluminum die casting service emerges as a beacon of precision. Leveraging cutting-edge technology, we execute the process with meticulous accuracy, injecting molten aluminum into intricately designed molds under high pressure. This dedication to precision is not merely a feature but a core value that defines our commitment to delivering components of exceptional quality. Whether for aerospace, automotive, or various other industries, our aluminum die casting service sets the standard for precision manufacturing, consistently producing components that meet or exceed the stringent dimensional requirements of diverse applications.

Welcome to Lvda Metal, a distinguished metal manufacturing company equipped with cutting-edge production facilities and a dedicated team of professionals ensuring superior quality.

Our comprehensive services encompass a one-stop solution for die-casting molds, injection molds, CNC machining, sheet metal processing, surface treatment, and packaging. With advanced technology and a commitment to excellence, we deliver precision-engineered products tailored to your specifications.

At Lvda Metal, our mission is to enhance the quality while minimizing costs for our customers. We have cultivated long-term partnerships with renowned companies, earning widespread acclaim for our commitment to excellence. As we continue to grow, we eagerly anticipate forging new collaborations, extending our expertise, and achieving mutual success with more valued customers.

With fourteen years of experience in manufacturing metal products, LVDA boasts advanced equipment and a professional technical team. The company has emerged as a leading manufacturer and solution provider in the industry, ensuring top-notch quality and service.

LVDA leverages its expansive production scale to drive down costs while continually innovating to enhance production efficiency. By embracing technological advancements, we optimize processes to deliver competitive pricing without compromising on quality.

Beyond mere production, LVDA offers invaluable engineering expertise throughout the manufacturing journey. From material selection and custom prototyping advice to cost-saving insights, our dedicated team provides expert guidance, ensuring optimal outcomes for every project.

As an ISO9001/IATF16949 certified factory, LVDA upholds the highest standards of quality assurance. We furnish comprehensive testing equipment and material certification reports, alongside tailored first sample inspection plans, guaranteeing the integrity of every component.

Aluminum die casting service enhances component strength, providing a remarkable strength-to-weight ratio crucial for demanding applications.

Aluminum die casting service reduces costs by delivering components with excellent surface finishes, often eliminating the need for additional finishing processes.

Absolutely, aluminum die casting excels in versatility, allowing for the production of intricate shapes and designs with precision and ease.

Industries such as electronics and automotive leverage the efficient heat dissipation of aluminum die casting for enhanced thermal performance.

Copyright © 2024 by Dongguan Lvda Metal Products Co., Ltd. - Privacy policy