Ensuring consistent quality in mass production is a paramount concern, and injection molds play a pivotal role in achieving this objective. The robustness of the mold design, coupled with stringent quality control measures, serves as a guarantee that each molded part meets the specified standards. The ability to produce components with minimal variation is not only indicative of the precision engineered into injection molds but also a testament to the commitment to quality assurance. In industries where uniformity is critical, such as medical manufacturing or automotive production, injection molds become the linchpin for maintaining and exceeding the expected levels of quality and consistency.

In the dynamic landscape of modern manufacturing, versatility is not just advantageous; it's imperative. Our injection molds embody this attribute, showcasing remarkable compatibility with an extensive range of materials. From standard thermoplastics to advanced engineering polymers, our molds adapt seamlessly, offering tailored solutions for diverse material requirements. This adaptability empowers our clients to choose materials based on the specific performance characteristics needed for their end products. The flexibility to work with a spectrum of materials positions our injection molds as versatile assets that cater to the evolving needs of industries with varying material demands.

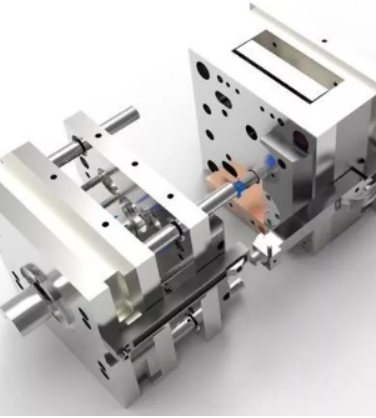

Innovation is not just a buzzword; it's the heartbeat of our injection mold manufacturing. Staying at the forefront of technology is not a choice but a necessity. Our commitment to research and development ensures that our molds are not just current but anticipate the evolving needs of the manufacturing landscape. By integrating cutting-edge technologies, such as advanced cooling systems and digital simulations, we lead the path to innovation in injection mold manufacturing. Our clients benefit from molds that are not only reliable today but ready for the challenges of tomorrow. Innovation and technology integration are not mere aspirations but guiding principles that position us as trailblazers in shaping the future of injection molding.

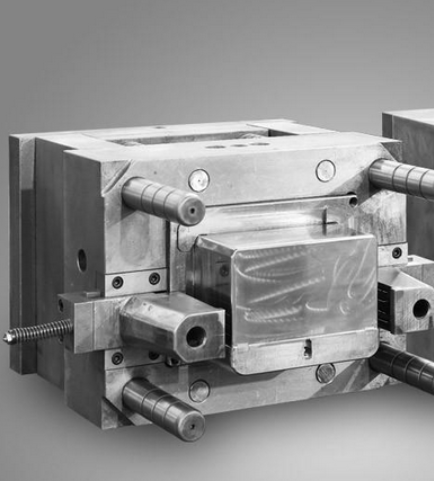

Precision excellence defines our commitment as an injection mold manufacturer. In a world where manufacturing demands exacting standards, our molds stand as testaments to precision engineering. Every mold we craft undergoes meticulous design and construction processes to ensure that the components produced exhibit a level of precision that surpasses industry expectations. From intricate automotive components requiring tight tolerances to the delicate features of medical devices, our injection molds consistently deliver top-tier components. Our unwavering dedication to precision is not just a trait but a foundational principle that shapes our entire manufacturing ethos.

Our injection mold manufacturing transcends being a service; it's a collaborative partnership. We understand that each client brings unique requirements and challenges to the table. Our team collaborates closely with clients, from initial design discussions to the final delivery of molds tailored precisely to their specifications. This collaborative approach ensures that our injection molds seamlessly integrate into diverse manufacturing processes, contributing to the success of our clients across industries. As partners in the manufacturing journey, we take pride in delivering injection molds that not only meet but exceed expectations, fostering long-term, mutually beneficial relationships. Our commitment to collaborative partnerships sets the foundation for a seamless and successful injection mold manufacturing experience that goes beyond transactional engagements.

Welcome to Lvda Metal, a distinguished metal manufacturing company equipped with cutting-edge production facilities and a dedicated team of professionals ensuring superior quality.

Our comprehensive services encompass a one-stop solution for die-casting molds, injection molds, CNC machining, sheet metal processing, surface treatment, and packaging. With advanced technology and a commitment to excellence, we deliver precision-engineered products tailored to your specifications.

At Lvda Metal, our mission is to enhance the quality while minimizing costs for our customers. We have cultivated long-term partnerships with renowned companies, earning widespread acclaim for our commitment to excellence. As we continue to grow, we eagerly anticipate forging new collaborations, extending our expertise, and achieving mutual success with more valued customers.

With fourteen years of experience in manufacturing metal products, LVDA boasts advanced equipment and a professional technical team. The company has emerged as a leading manufacturer and solution provider in the industry, ensuring top-notch quality and service.

LVDA leverages its expansive production scale to drive down costs while continually innovating to enhance production efficiency. By embracing technological advancements, we optimize processes to deliver competitive pricing without compromising on quality.

Beyond mere production, LVDA offers invaluable engineering expertise throughout the manufacturing journey. From material selection and custom prototyping advice to cost-saving insights, our dedicated team provides expert guidance, ensuring optimal outcomes for every project.

As an ISO9001/IATF16949 certified factory, LVDA upholds the highest standards of quality assurance. We furnish comprehensive testing equipment and material certification reports, alongside tailored first sample inspection plans, guaranteeing the integrity of every component.

Injection molds accommodate a range of materials, from standard plastics to high-performance polymers. Material selection influences product durability, strength, and other key properties.

Injection mold costs depend on complexity, material choice, and volume. Optimizing design for manufacturability, selecting suitable materials, and leveraging economies of scale contribute to cost-effectiveness.

Yes, injection molding supports rapid prototyping, allowing for the creation of functional prototypes with production-grade materials. This method provides a realistic representation of the final product's form, fit, and function.

Implementing robust quality control measures, regular maintenance of molds, and utilizing advanced molding technologies contribute to maintaining consistent and high-quality production, even for critical components.

Copyright © 2024 by Dongguan Lvda Metal Products Co., Ltd. - Privacy policy