- Overview

- Inquiry

- Related Products

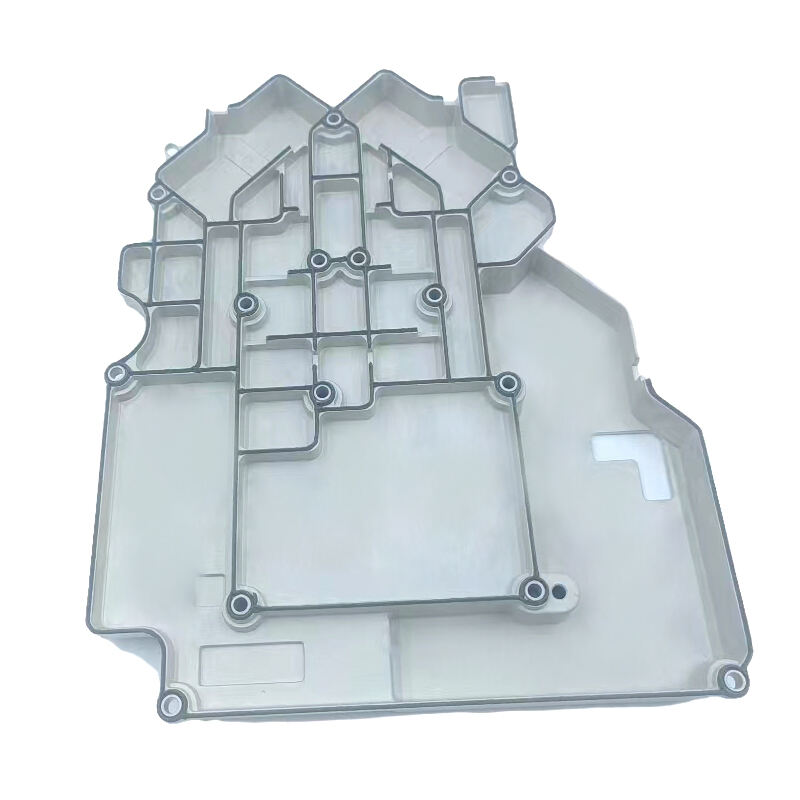

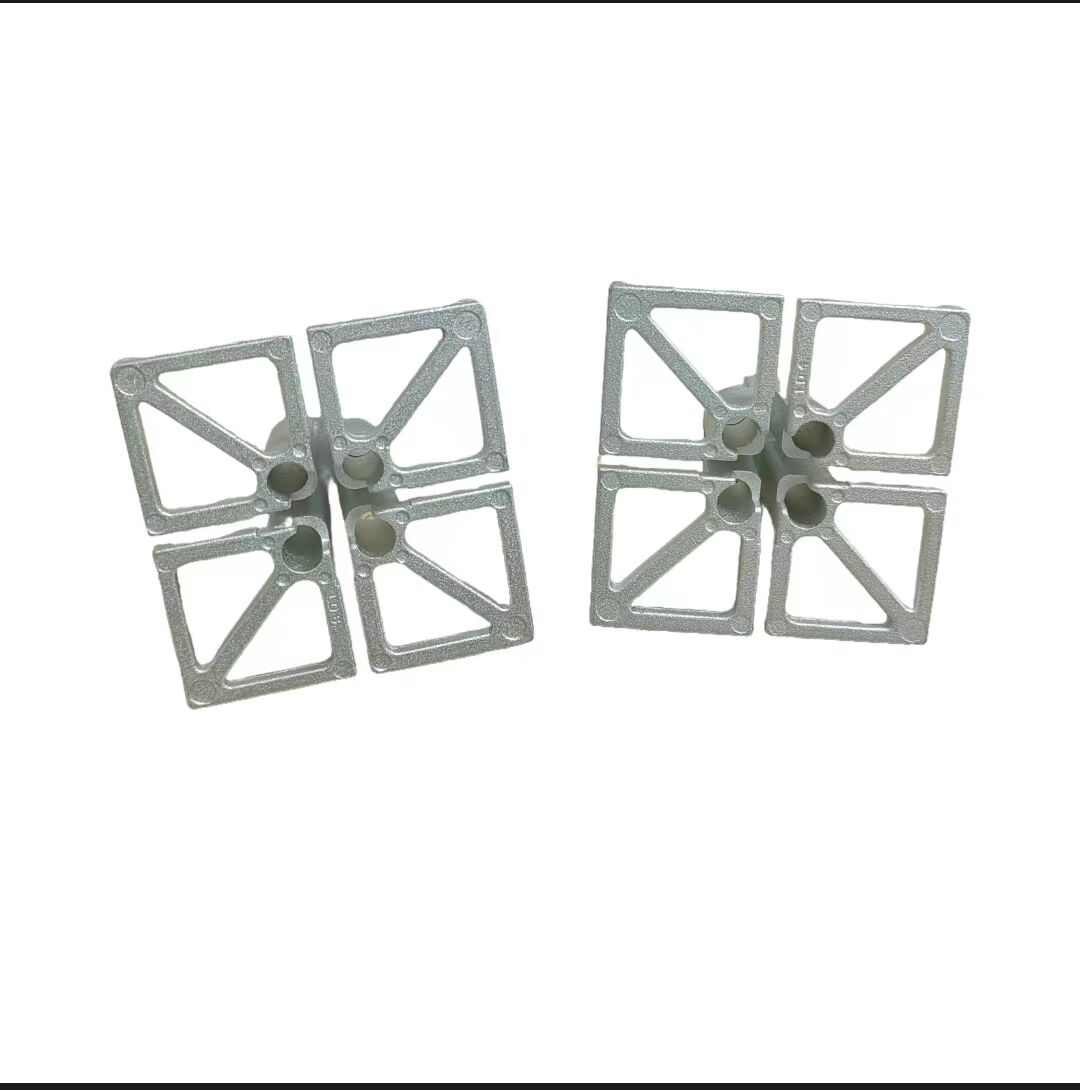

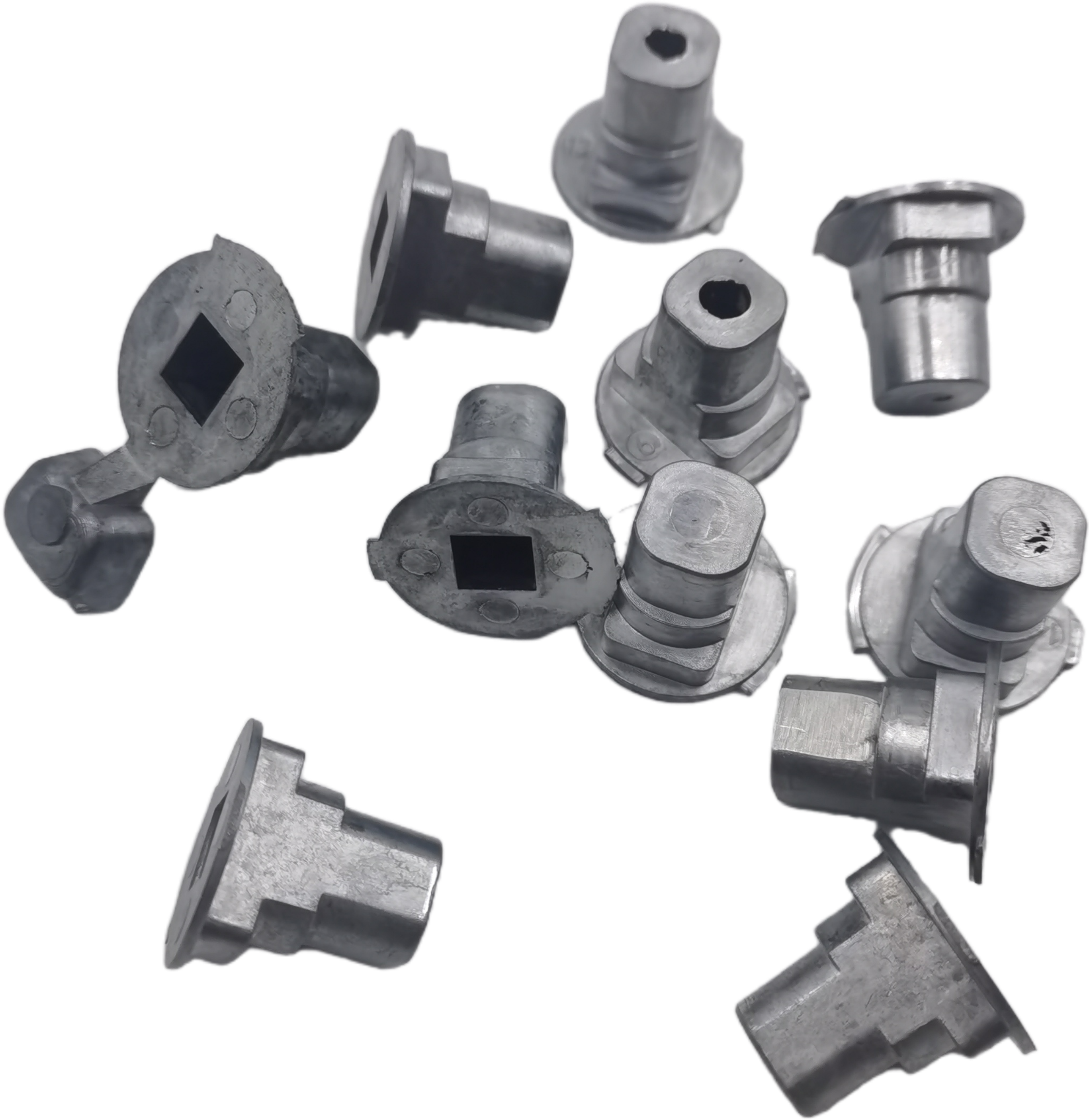

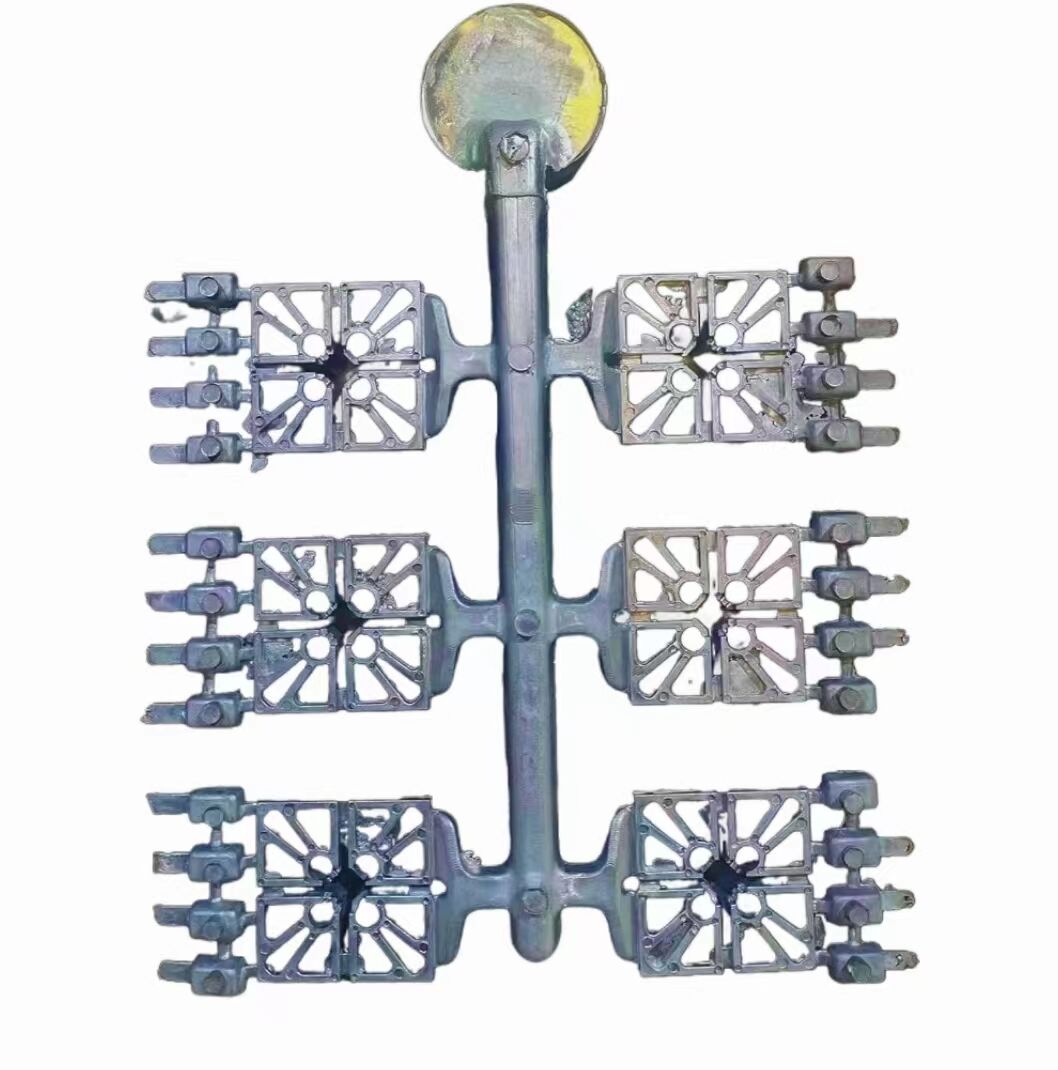

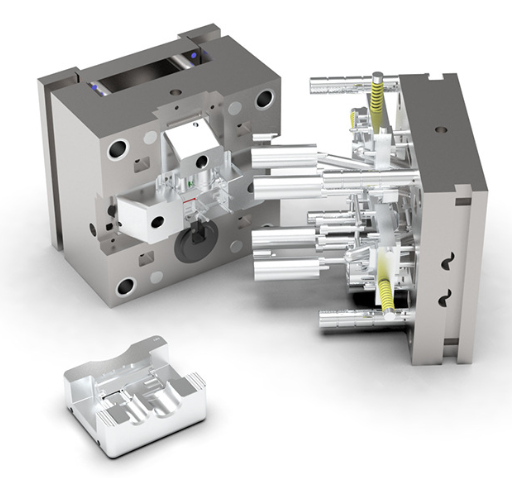

Die casting, a metal casting process.

It is characterized by using the mold cavity to apply high pressure to the melted metal.

The liquid or semi-liquid metal is filled with the die casting cavity at a high speed, and the casting is formed and solidified under pressure.

Short filling time and fast forming cycle. Advantages of die casting process:

The product quality is good, the casting size is accurate, the strength and hardness is high, which is 25%~30% higher than the general sand casting, and the size is stable, the interchangeability is good, and the casting can be die-cast thin wall complex castings.

High mechanical productivity, high production efficiency, long die casting life, accelerate the realization of mechanization and automation.

Excellent economic effect, precise size of die casting, smooth and smooth surface, generally no longer for mechanical processing and direct use,The latter processing amount is very small, so it not only improves the metal utilization rate, but also reduces a lot of processing equipment and working time.

Understand the die casting process, if you are interested, please feel free to contact us.