- Overview

- Inquiry

- Related Products

In the field of precision casting, our die-casting products adopt advanced die-casting technology to ensure precise dimensions and smooth surface, whether it is complex structure or fine texture, can be accurately rendered, adding unique charm and reliability to your project.

From the careful selection of raw materials, to the strict control during the die-casting process, to the fine treatment at the later stage, each step contains professionalism and rigorous attitude.

Our die-casting products are not only industrial parts, but also a strong support for quality of life and high-end manufacturing. Widely used in automobiles, electronics, machinery, life in the home appliance industry and so on, with stable performance and excellent durability, to win the trust and praise of customers. Choose our die-casting products, favorable price, quality is guaranteed, support to customize.

From design to finished product, die casting production is a rigorous and complex process that involves a number of key steps, each of which needs to be precisely controlled in order to ensure the high quality and performance of the final product.

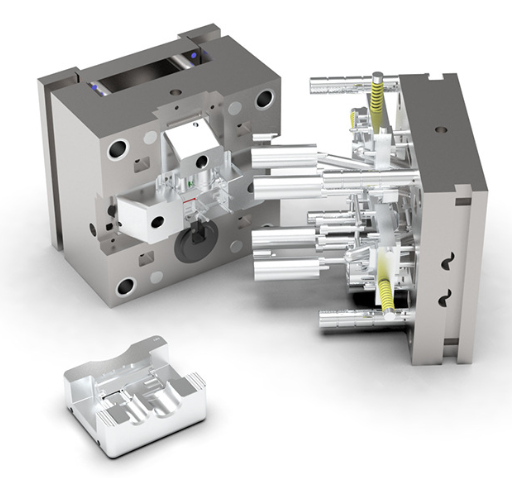

Product mold design: according to customer requirements and product specifications for product 3D modeling and mold structure design, design is completed using high-precision processing equipment to manufacture molds.

Raw material preparation and melting: according to the product characteristics of the selection of suitable die-casting alloy materials, such as aluminum alloy, zinc alloy and so on. Raw materials are put into the melting furnace and heated to liquid state, and the temperature is strictly controlled. Time and alloy composition ratio.

Die-casting molding: through the die-casting equipment will be prepared metal liquid into the die-casting machine mold cavity, die-casting machine through high-pressure fast metal pressure into the mold, so that it in the cavity quickly cooled and solidified molding. Here you need to accurately set the die-casting parameters, to ensure product molding quality and production efficiency.

After treatment and finishing: die-casting molding products need to carry out a series of post-treatment processes, including the removal of sprues, flying edge, surface treatment (such as shot blasting, sand blasting, electroplating, painting, etc.) to improve the appearance and improve corrosion resistance. For some parts of the requirements of high-precision products need to be CNC machining.

Quality inspection and control: Throughout the production process, comprehensive quality inspection and control is implemented, utilizing a variety of inspection means, such as CMM, spectral analyzers, etc.