Sheet Metal Fabrication: The Backbone of Industrial Manufacturing

Introduction: Comprehension of Sheet Metal Designing

Various industries like automobile, aerospace and construction heavily rely on sheet metal fabrication. This involves cutting, folding or welding of flat metal sheets into functional parts or structures. The method enables the creation of light weight but strong structures as well as large scale production with high accuracy and uniformity. In this article we are going to talk about what it does and where it is applied.

Significance Of Sheet Metal Fabrication

Flexibility and cost effectiveness make sheet metal manufacturing an important part of the production process in any industry. Custom designed metals that can withstand heavy usage or extreme conditions may be produced using this method. It is known for its ability to hold exact dimensions within given tolerances thus yielding high quality outputs every time without fail.Sheet metal fabrication also aligns with sustainable practices by minimizing wastage since all parts of a given size are made out from one piece only.

Sheet Metal Fabrication Techniques

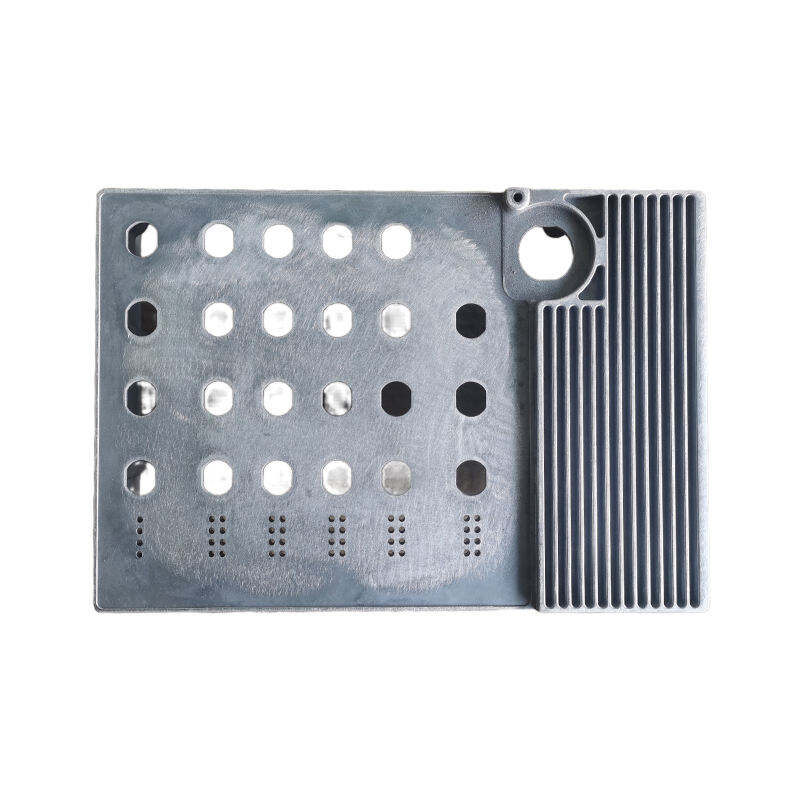

A number of different methods are employed during the course of working on materials such as these so as achieve desired results; among them being punching、laser-cutting、CNC machining and welding.Punching entails using punchers along with die sets which cut out shapes from sheets while laser cutting makes use of highly powered lasers which slice through metals precisely according to required measurements.The latter involves computer numerical control systems managing tools used in various operations performedc on metallic sheets whereas welding joins two or more pieces together usually by heating edges until they melt into each other.

Applications Of Sheet Metal Fabrication

The uses for sheet metal fabrications are many and varied too.For instance in the automotive sector they can be used when making body panels, chassis components or even exhaust systems.In aerospace industry such could be applied during manufacture aircraft skins、air ducts or fuel tanks.Construction firms would also heavily depend on them especially while creating window frames、roofing materials etcetera.Electronics require casings and heat sinks which are only possible through this process.

Conclusion: Embracing The Future Of Sheet Metal Fabrication

Sheet metal fabrication is a critical component in the manufacturing industry that provides strength, accuracy and customization for various parts used across different sectors.As new technologies continue to emerge so do methods employed in sheet metal fabrication thus ensuring its relevance within industrial production forever.With innovative approaches together with advancements made towards these methods; it will always remain at the heart of manufacturing processes worldwide.