Future Directions in Rapid Prototyping

Understanding Rapid Prototyping

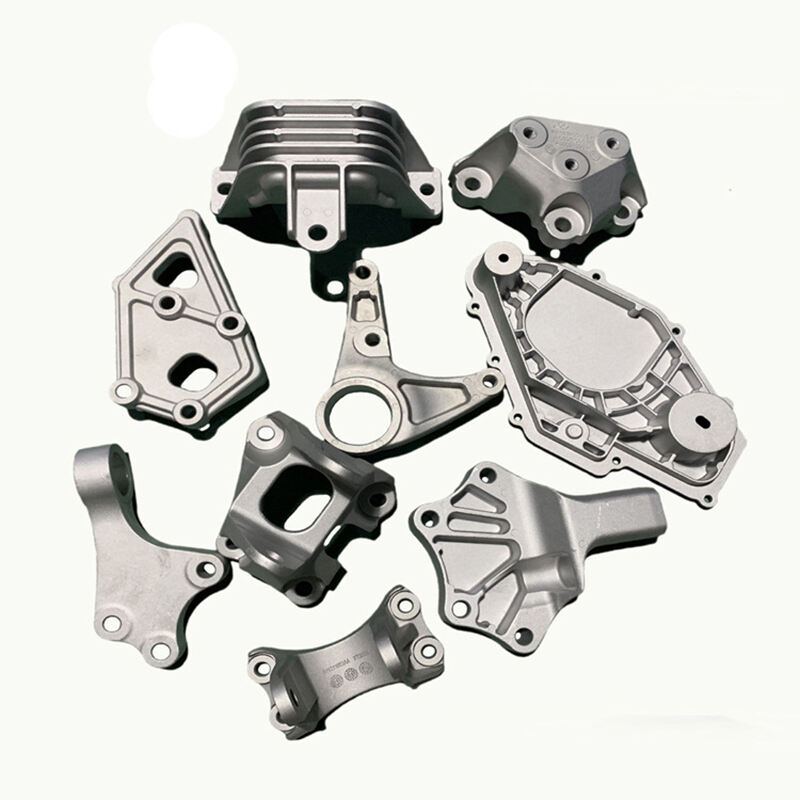

Rapid Prototyping is a process employed in the development of models of physical parts quickly. Through the employment of CAD data, users can easily create 3D geometric models. As a result, the design of a wide variety of products can be done much faster and at a lower percentage of cost. Rapid prototyping is also employed in LVDA Metal, thereby allowing the firm to manufacture quality products and meet client expectations in terms of time.

The Function of LVDA Metal in Rapid Prototyping

LVDA Metal is one of the most professional metal manufacturing firms that use rapid prototyping almost exclusively. With trained professionals and advanced production equipment for control of quality, LVDA Metal can be able to offer a one-stop solution to clients. Customers have a wide range of needs and LVDA meets them all with products ranging from die-casting molds, injection, CNC machining processes, sheet metal handling, and surface treatment, all the way to packaging.

Technological advancements and their impact on RPT

Rapid prototyping is a result of technology and LMDA metal recognizes that all future depends on the advancement of technology. That is why, we constantly invest in modern equipment and software such as CNC, laser cutting, and 3D printing among others. With these tools at our disposal, we can prototype even more complex and precise parts which broaden the scope even further for metal working.

Road to RPT: “Manufacturing"has new challenges

Eco-friendliness has now become a buzzword in the manufacturing industry, LVDA Metal has recognized this trend and is looking to make eco-friendly innovations in their rapid prototyping. Such integration would include using recyclable materials, redesigning to minimize waste and therefore using less harmful resources, and energy-efficient production methods one might say. Such measures would mean that the environmental impact would be declining without compromising on quality standards.

Collaborative Design and Rapid Prototyping

LVDA Metal promotes collective effort in the design, engineering, and manufacturing phases which in turn enhances the realization of the prototypes. Rapid prototyping projects realize potential through collaboration where ideas are shared and new ones conceived. The focus of LVDA Metal's engineering support team is to partner with clients to offer the right advice on materials, prototypes, and how to produce them. This integration of resources not only ensures understanding but also guarantees that the client’s built idea is replicated accurately.

The dynamism of rapid prototyping architecture is changing with technology. Rapid Prototyping is the key focus of LVDA Metal as they are ready to optimize these new capabilities to serve our clients. How we machine components, how we design them, how we build them with environmental thinking, or how we achieve tight tolerance — All of those practices help us to provide high-precision manufactured parts of the desired quality.