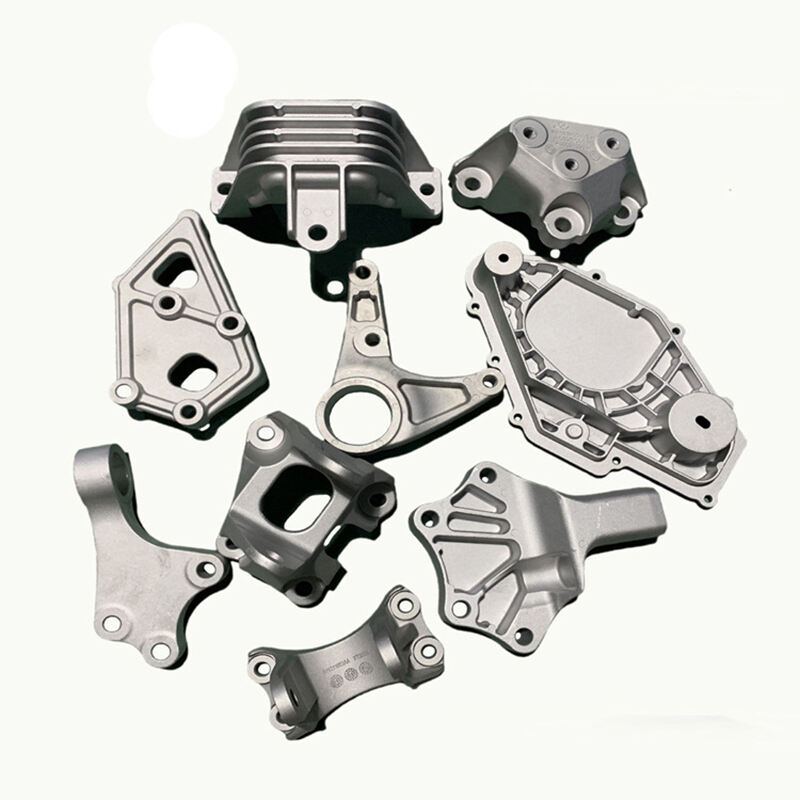

Application of Aluminum Die Casting in High Complexity Parts

Aluminum die casting is a metal casting process wherein molten aluminum is injected into molds fabricated in steel at high pressure. This technique allows for the fabrication of intricate and complex components with a higher degree of accuracy and the potential of being reproduced many times over. We guarantee quality because we are sure enough that every single piece produced is indeed a fine piece of work.

The Applications of Aluminum Die Casting

Aluminum die casting’s most noticeable advantage would be its versatility. Aluminum has a low density and high strength-to-weight ratio which makes it useful in many different workflows. From auto parts to consumer electronics, aluminum die casting has been an important part when creating parts that require high strength but need to be lightweight. LVDA Metal uses this technology so that they can manufacture parts that are strong but also need to meet the weight specifications.

Aluminum Die Casting - Complex and Synthetic Precise Solutions

The strength and precision of aluminum die casting cannot be compared to anything else. This process also provides an opportunity for achieving strict tolerances. In the end, the product differs with respect to the original design by an irrelevant degree. Here, at LVDA Metal, we employ cutting-edge technology and expert craftspersons in the endeavor to ensure that every casting that leaves our premises is the most accurate one possible. The effect of temperature is especially important in cases where the part to be cast has high complexity in the form of thin-walled and intricate parts.

Low-Cost in Mass Production

Precision is key with aluminum die casting but so is the cost when creating parts on a larger scale, such as parts with the same mold with slight differences. The one-time expenditure incurred for mold designing, alongside the fast production cycles and inexpensive labor costs, works to their assist. LVDA Metal is known for providing highly competitive prices for our aluminum die castings without compromising on quality. Therefore, we are one of the most favorable options for customers who are looking for quick and efficient solutions.

Aluminum Die Casting and Sustainability

At LVDA Metal, sustainability is a goal that sits at the very heart of our activities. Aluminum scrap forms part of our die casting process so minimizing waste is a given since aluminum is a recyclable material. This not only positively affects the environment but also aids the economic feasibility of our products. Conclusively, we are committed to developing and enabling methods of sustainable practice across our production operations.

Aluminum die casting offers a unique solution that has the ability to manufacture intricate parts with great accuracy and speed. LVDA Metal has adopted and uses this technology in the creation of high-quality products for a variety of companies in the industry. We are committed to accuracy, cost competitiveness, and environmental protection which makes us stand out from the competition dominantly in aluminum die casting.